Lighting for clean rooms

What is actually behind it?

#Clean rooms can be found in healthcare & nursing, in the chemical industry, in clinics & hospitals, in the food & cosmetics industry as well as in industry & commerce.

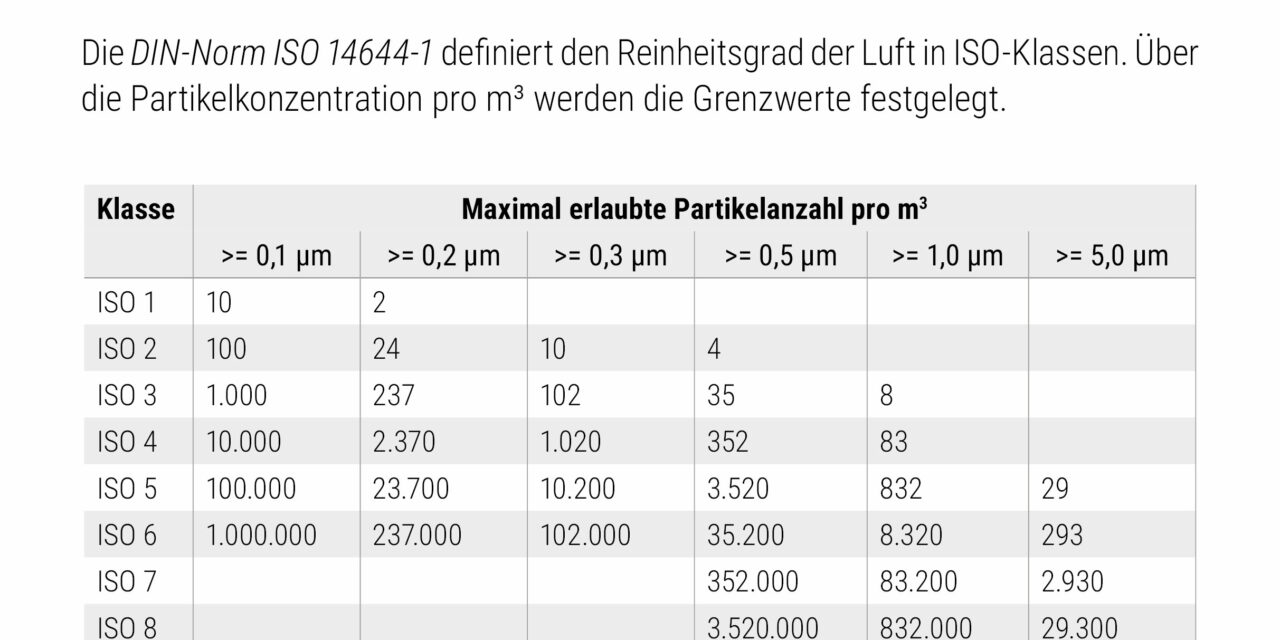

Clean rooms place particularly high demands on the environment. The number of particles must be reduced to a minimum so that no contamination occurs during the processes and manufacturing procedures taking place in the room. Examples include the production of medicines or computer chips. Particles are released by people, the equipment in the room, but also by manufacturing processes. VDI Guideline 2083 provides a uniform and cross-industry description of processes and specifications for clean room technology. Cleanrooms are defined by the so-called cleanroom classes. The individual classes describe the maximum permissible concentration of airborne particles that may not be exceeded in a cleanroom.

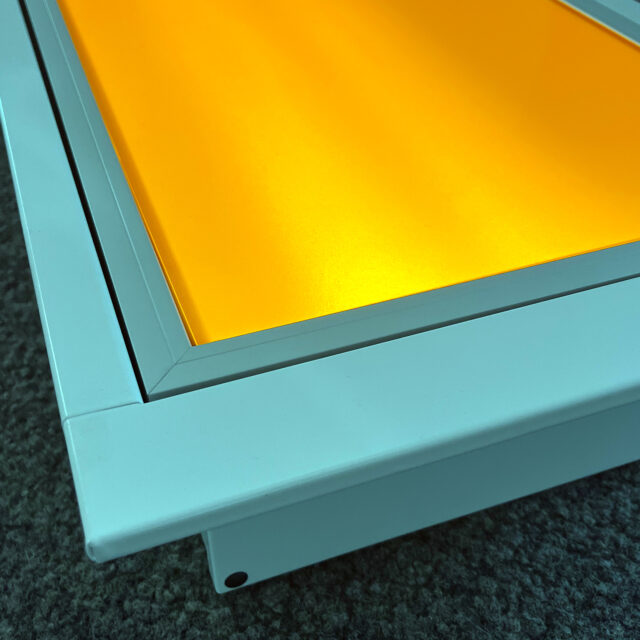

The subject of lighting for cleanrooms is complex – the solutions are always individual. Quality factors play a major role. Technical values such as lumens, luminance, glare control and illuminance in the classical sense for lighting design. Clean room and #cleanliness suitability is also manifested in particle emission, cleanability, chemical resistance and biological metabolisability.

Luminaire production in our in-house clean room is tested according to DIN EN ISO 14644 and has been an integral part of our production lines since 2016. The quality factors are proven for Regiolux by certifications.