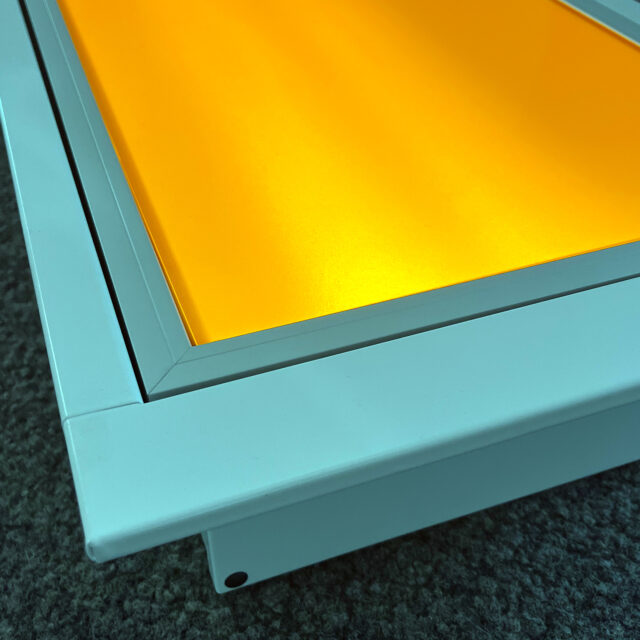

Regiolux has reached another milestone in its #innovation history. We are proud to present our new #profiling machine. This state-of-the-art machine is specially designed to produce the #gear trays for our #trunking systems and to run through the entire production chain from raw material procurement to the finished component.

→ But what makes this machine so special?

Digital networking and customised development

The development of the profiling machine was the result of months of intensive collaboration with our supplier. Together, we designed a production system that is not only state-of-the-art, but also digitally networked within the company. This digital networking enables us to monitor production processes in real time, increase efficiency and react flexibly to changes.

Extended production steps and improved quality

Compared to our previous processes, the machine offers a range of additional production steps that enable more comprehensive processing of the device carriers. From straightening and punching to profiling, labelling, pressing and stacking – a large number of processing steps are combined under one roof. This enables us not only to improve the quality of our products, but also to increase flexibility in production.

Forward-looking technology for long-term success

By investing in the roll forming system, we are creating the basis for state-of-the-art production in a product area that is important to us. By integrating innovative technologies and creating a networked production environment, we are setting standards for efficiency, quality and flexibility. We look forward to continuing to supply our customers with high-quality and reliable continuous-row lighting systems.