In many production processes, light is not only a practical necessity, but also has a direct influence on the quality of the manufactured products. Especially in photosensitive areas such as #dental technology, #3D printing or #semiconductor manufacturing, light can trigger certain chemical reactions – even undesirable ones. This is precisely where #yellow light plays a crucial role, and Regiolux offers innovative lighting solutions to meet these challenges.

Why can blue and UV light be problematic?

Some photosensitive production processes react sensitively to light in the blue and UV spectrum. These include

- Dental fillings: These photosensitive materials cure under UV light. Blue light can also accelerate the curing process. It must therefore be avoided during production.

- Lithography processes (such as 3D printing): These processes are sensitive to blue and UV light, as these can influence the hardening or structuring of the materials.

- UV-curing lacquers: In the production of special lacquers that are to be cured later under UV light, even the smallest amount of blue light in the environment can lead to problems. These lacquers could react unintentionally early, which could disrupt production and quality.

The solution: production under yellow light

To avoid these undesirable effects, these special manufacturing processes must take place in the absence of blue and UV light. This means that the light in the work areas must be filtered – this is where yellow light comes into play. Yellow light is free of blue and UV light components and ensures that the sensitive materials and processes are not disturbed. This type of lighting is particularly essential in #cleanrooms – for example in semiconductor production or lithography.

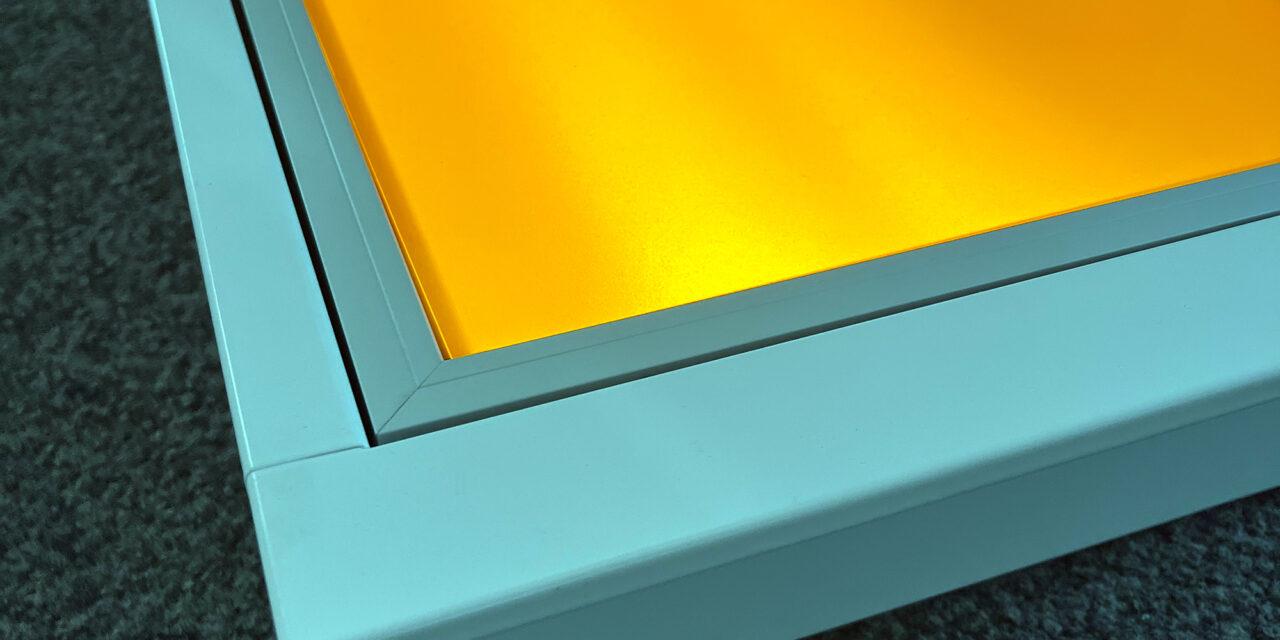

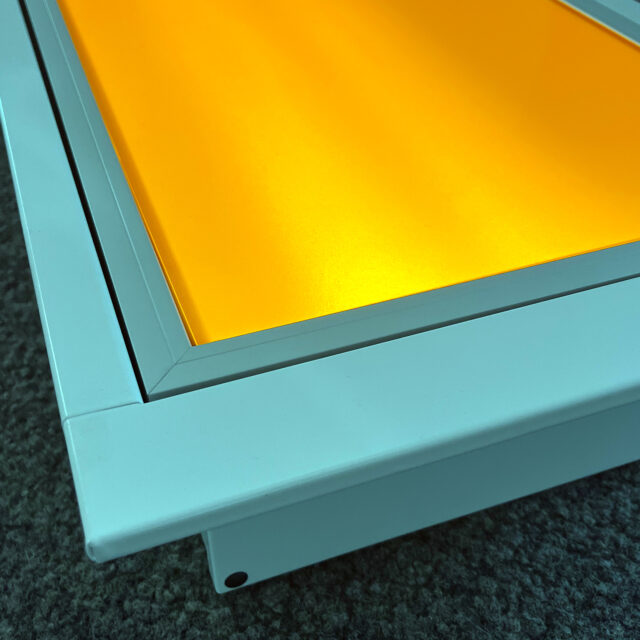

Regiolux and the yellow filter

At Regiolux, we offer lighting solutions that are specially tailored to such sensitive applications. Our luminaires, such as the protection or the aduna, can be equipped with special yellow filter discs. These filters reliably eliminate all blue light components of the installed LEDs and thus create a safe production environment.

We have already successfully realised such projects with our quick mounting system and the protection series. These solutions enable uniform illumination and do not impair sensitive processes.

Conclusion: Yellow light – a small difference with a big effect

The right light is crucial for success and quality in production. With Regiolux’s yellow light solutions, we offer you the opportunity to optimally support sensitive production processes while ensuring the highest lighting standards.