The industry is on the brink of a significant change: away from classic 400VAC systems towards more efficient, future-oriented DC direct voltage networks. This new technology, based on a voltage of 650VDC, promises to fundamentally change the way industrial systems are operated. At Regiolux, we have been looking closely at the possibilities and benefits of this development and see the switch to DC systems as an opportunity not only to increase energy efficiency, but also to create a more sustainable future.

What is the #DC Grid?

At its core, the DC grid is about the direct utilisation of #direct current (DC) in industrial plants. Instead of converting the electricity several times – from #alternating current (AC) to direct current and back – the DC Grid enables more efficient energy transmission and utilisation. This technology is being driven forward by the Open DC Alliance (ODCA), an organisation under the umbrella of the ZVEI, which now has over 70 companies as members – including well-known companies such as BMW, Wago, Kuka and Phoenix Contact.

Why DC?

- There are fewer conversion losses. In a classic AC system, a lot of energy is lost because electricity is converted from AC to DC and back several times. In a pure DC system, there are hardly any such losses. The braking energy of the robots and linear drives can be stored and utilised directly in the industrial plant itself.

- DC systems can be more easily connected to renewable energies. This increases the efficiency and sustainability of the system.

- Saving energy and costs: By switching to a DC network, Schaltbau was able to achieve around 15 % more efficiency. In addition, up to 40 % less copper is required when installing new systems. This reduces material and energy costs. Schaltbau, for example, was even able to reduce its energy costs by 35 %.

- Greater reliability and fewer production outages: DC grids are safer and more stable as energy reserves are available. In the event of blackouts on the public AC grid, DC companies can keep their systems running and shut them down in a defined manner if required. This ensures self-sufficient system operation and enables production to be restarted quickly without any loss of time.

Regiolux and DC Grid – Our path to a solution

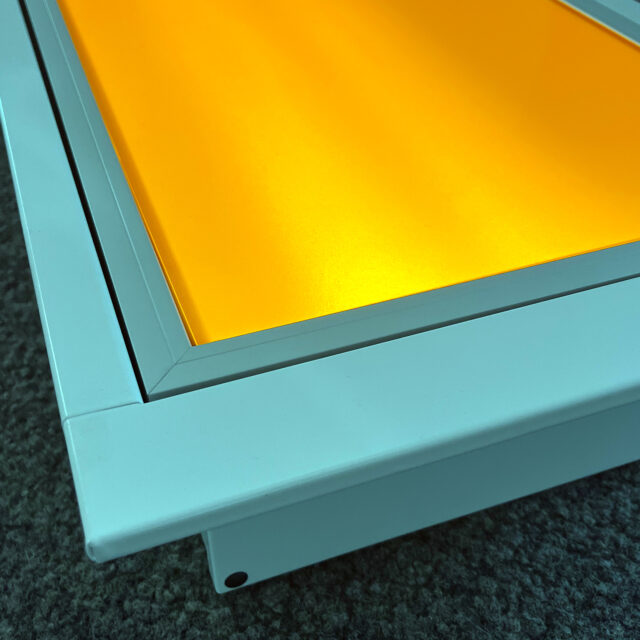

At Regiolux, we are intensively studying the requirements of a DC system and are working on developing solutions that optimally integrate our continuous-row lighting system into industrial DC networks. At the same time, we are developing concepts to fully utilise the advantages of DC networks through adapted wiring and innovative driver technology. We attach particular importance to proceeding in an energy-efficient and resource-saving manner. Our aim is to create a DC-compatible solution that can be seamlessly integrated into existing or new DC systems without the need for costly modifications. The proven product properties and product diversity of our quick installation system are a key focus for us.

Sustainable lighting and energy saving

Our DC-compatible lights not only contribute to a general increase in efficiency, but also use recuperated braking energy and photovoltaic energy directly, which further optimises the system’s own consumption. Our lighting systems make a significant contribution to overall efficiency and are part of a DC ecosystem.

Conclusion: DC Grid as the key to energy efficiency

As part of this movement, we at Regiolux are proud to promote innovative lighting approaches that meet the requirements of the future. With our DC-compatible products, we want to support companies in the future in making their systems not only more efficient, but also more environmentally friendly – while maintaining or even improving their overall performance.